THE JOURNAL

The humble T-shirt has had many lives. A descendent of the sporting Henley shirt, it was first worn as smock-type garment in warmer climates, before becoming a standard-issue undergarment for men. Then, in the 1950s, when screen stars such as Messrs James Dean and Marlon Brando shrugged off their starched shirts in favour of plain white tees, it was transformed into a symbol of youthful rebellion. By the 1980s, the T-shirt was ubiquitous and it remains a staple of our wardrobes to this day, worn everywhere from work to working out.

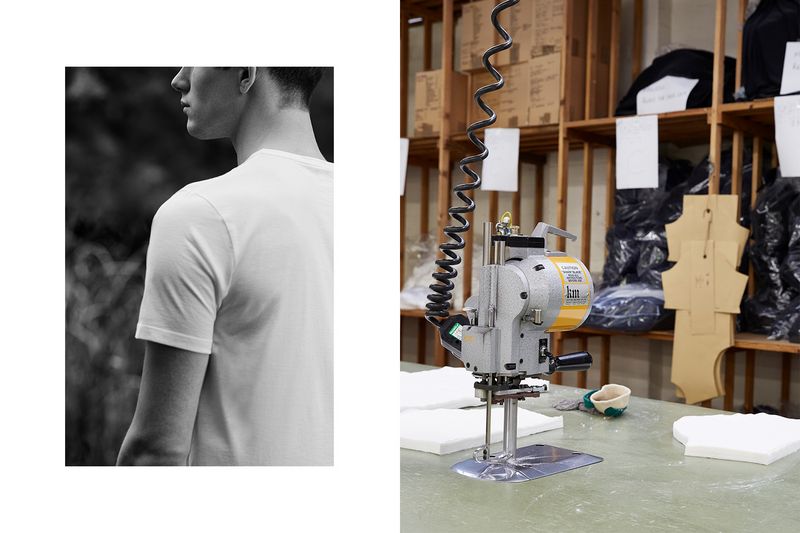

Throughout that history, Sunspel has been there. Founded in England in 1860 by Mr Thomas Hill, the son of a hosiery maker, the brand began making T-shirts around the time they were first beginning to be worn. Back then, the factory was one of the first steam-powered operations in the nation. But aside from making the switch to electricity, very little has changed in the actual manufacture of its T-shirts over a hundred years. “Sewing machines have gotten faster and better, but it’s still done by hand including the fabric cutting,” the brand’s CEO, Mr Nicholas Brooke tells MR PORTER.

Despite the brand’s storied past, Brooke is all too aware that heritage doesn’t equal quality. “It’s dangerous when brands rest on their laurels,” he explains. “And we definitely don’t do that.” Where other labels may fail to live up to their storied pasts, Sunspel’s continued success comes down to the fact that, at its core, it is a textile business. “We have always designed the T-shirt and all our clothes from the source itself,” Brooke says. “We are, and always have been, involved in every step of the creation process. And, as a result, we have an enormous attention to detail for every step.”

But while fit, cut, stitching, dye and any number of particulars are all crucial factors in the making of a Sunspel T-shirt, the real secret to a well-crafted tee starts at the very beginning of the production process: with the cotton. The brand maintains complete oversight over its supply chain, ensuring its raw materials are produced in a sustainable way that doesn’t waste water resources. The Q82 jersey – named for the two-fold 80s yarn it is crafted from – used for the Classic Sunspel tee is made from fine Supima cotton, sourced from California. The extra-long staple fibres are layered on top of one another to create a two-fold, which means that they don’t fuzz or fray like shorter varieties, and result in a much harder-wearing product that still retains a silky smooth finish.

In fact, the exceptionally high quality of the jersey makes it tricky to work with, requiring especially skilled artisans to turn it into tees. And so, to this day, the Classic T-shirt is crafted in the brand’s Long Eaton factory, a proud-looking redbrick on the outskirts of Nottingham in the midlands of England that’s served as the headquarters since 1937. Notably, it is the only luxury T-shirt company to still produce its tees in the UK. It’s an expensive operation, but, as Brooke explains, he wouldn’t change a thing. “Moving the factory would have been like taking the soul out of Sunspel… The people are part of the brand, too, and the local community around the factory is part of the brand,” he says.

The longest-serving member of staff, who was employed by the brand for more than half a century, only recently retired when the pandemic broke out. “A lot of the people who work in the factory have been with us a very long time,” Brooke says. “And it has a very family feel, actually.” Quite literally, it turns out. Since the skills needed to work at Sunspel are so specialised and rare these days, many of the workers are relatives, having been recommended by their uncles, aunts, parents and grandparents. “That’s why it has this strong community feel about it and that’s why it is so special to the brand,” Brooke says.

While the manufacturing process and artisans behind the brand may be a constant, the design is something that Sunspel is happy to tinker with, and it has spent years perfecting the recipe, so to speak. “We are continually improving things. The fit has to change to suit people’s shapes, people’s heights and what people are wearing with T-shirts,” Brooke explains. “The Sunspel T-shirt has been refined over a hundred years. It’s always been made from the finest cotton; it’s made to stand up to the test of time; to fit superbly; to be exceptionally comfortable, and to become a customer’s wardrobe favourite.” And we can’t think of a better definition of luxury than that.