THE JOURNAL

We all know watches pack some pretty complex movements into a small space. But just how tiny – and how difficult to make – they are might surprise you. Switzerland’s finest watchmakers go to huge lengths to make minuscule mechanics, which tick to tolerances imperceptible to the naked eye. Even if you can see the movement under a skeletonised dial or through a sapphire case back, you can’t see just how incredibly precise the movement really is. We’ve picked out seven of the smallest-scale wonders, common to every single mechanical watch, to remind us just how much goes into the task of telling the time.

01.

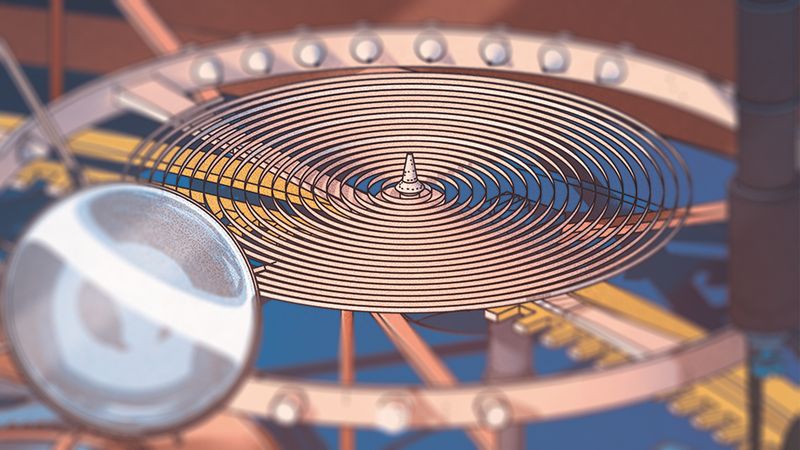

A delicate balance spring

The spiral balance spring is the beating heart of a mechanical watch. Weighing in at 2mg, it is as light as an ant and just as hardworking. It oscillates 200 million times a year with unerring regularity, eking out the flow of energy through the entire movement, measuring out that seemingly frantic tick in quarter-second intervals. No thicker than a quarter of a human hair, balance springs start life as 0.25mm wires of iron-alloy Nivarox, made by a single German company in Hanau. These are “drawn out”, rolled into a 0.02mm-thick tape before being coiled into a perfectly concentric hairspring.

02.

The tiniest nuts

At just 0.3mm in diameter, with a 0.18mm bore hole, a watchmaker depends on the smallest nuts in the world (as recognised by Guinness World Records) to tweak the precision of the balance assembly. Known as regulating the balance, it’s a skilled job fundamental to the watch’s proper function. Screw the nuts in and the wheel will turn quicker, and vice versa, controlling the rate at which the watch ticks. Each nut is threaded to four or more bolts protruding from the rim of the balance wheel, which oscillates about the axis of the spring.

03.

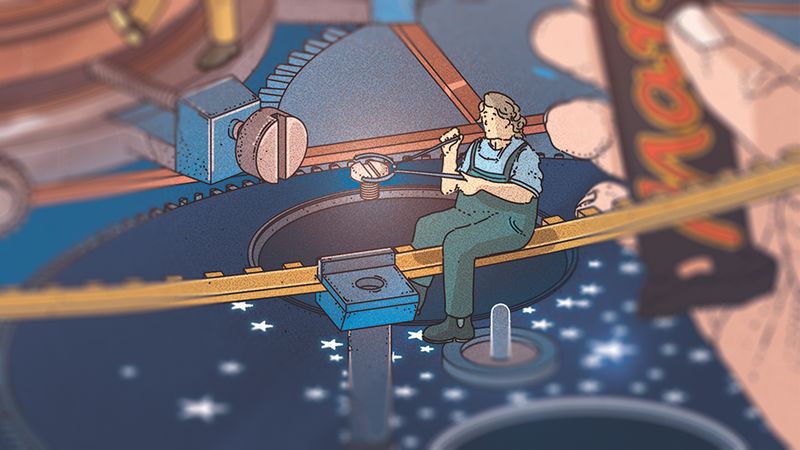

And the screws to match

Profile turning, where spinning bars of raw metal are “roughed out” by computer-programmed drill bits with fully 3D trajectory, has become so sophisticated that a baseplate’s screw can be machined within a tolerance of three thousandths of a millimetre, or three microns. In other words, we’re talking about an operating margin stretching a single bacterium’s length. This is one job machines have been able to improve, but a watchmaker still has to fit the tiny screw by hand (ok, by tweezer).

04.

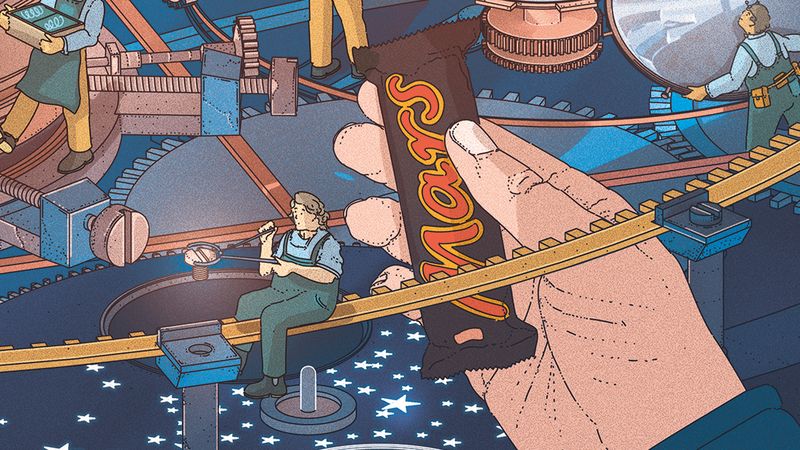

The ultra-efficient movement

The energy store of every mechanical watch movement is its winding barrel: a 20-30cm ribbon of hair-thin nickel-cobalt-chromium steel alloy, which is either automatically wound by your arm’s movement, or needs to be hand-wound. Assuming a pretty average 42-hour power reserve, when the watch is fully-wound, the spring stores half a joule of energy. Thanks to the infinitesimal efficiency of a typical mechanical movement, this means a Mars bar could power the industry-standard ETA 2824-2 calibre for 8,767 years.

05.

The slowest-moving component

A perpetual calendar ranks as one of the handiest and most prestigious complications, capable of correctly adjusting for the length of every month including leap years. Running this function – think a primitive CPU – is horology’s slowest-moving component: the cam of 48 programme wheel. It’s notched 48 times to varying depths depending on the length of each month in a leap-year cycle, and takes that time to make a full rotation. Meaning the 24mm circumference cam in IWC SCHAFFHAUSEN’s calibre 52615, for example, travels at a glacial speed of 0.000000000426mph.

06.

A drop of oil (that lasts five years)

Imagine running your car without oil; not a pretty thought. Lubricant is crucial to a watch’s smooth operation, but a single thousandth of a millilitre of oil is enough to ensure a movement ticks over nicely for five whole years, before friction dries each point to a varnish and you’re due another service. Thanks to advances in synthetic lubricant, that’s significantly up on ye olde industry standard: neatsfoot, which is extracted from the boiled fat glands of cattle.

07.

The toughest jewels

Hard-wearing synthetic rubies (as well as oil) are found at every movement’s critical pivot point, chosen for their durability and low friction. These red jewels, twinkling through your watch’s case back, are made the same way as the sapphire crystal that covers them: alumina (Al2O3) powder melted at 2,000ºC, forming onto seed crystal that’s then exhaustively machined into discs about 1mm in diameter and 0.1mm high. These are then laser-pierced with pivot holes 0.07mm-0.5mm across.

Illustration by Mr Doug John Miller