THE JOURNAL

Put your hands up for Detroit: the leather design room at Shinola’s factory in the city’s New Center neighbourhood

Paris… Milan… Detroit is not the usual drum roll of style capitals, but Shinola’s affordable luxury goods are becoming a beacon of American craftsmanship.

Built in Detroit. It is a simple declaration of provenance. This city, after all, was long synonymous with industriousness and know-how – applied not just to any old product, but also to the automobile, an icon of the American Dream. Then a darkness fell over the town. During the Great Recession of 2009, two of the big three automakers (Chrysler and GM) filed for bankruptcy. The city itself filed for bankruptcy in 2013, and it has become the country’s first post-apocalyptic metropolis in popular imagination.

But out of this burned-out husk an unlikely success story has blossomed – oddly enough, a lifestyle brand. Launched in 2011, Shinola has been turning out watches, bicycles and leather goods. In the process, the company has put more than 200 people to work at its headquarters in the Argonaut, a 1930 Art-Deco building that once was home to a General Motors research facility. The company makes an honest attempt to source American, when possible. (Shinola’s bicycles are assembled from American-made and foreign parts about a 10-minute drive away; most leather goods are made in Missouri, about 600 miles south, although some small leather goods are now made in Detroit.)

Shinola HQ: a listed Art-Deco building called the Argonaut, previously owned by General Motors. It also houses the city’s College of Creative Studies

Shinola’s creative director Mr Daniel Caudill, previously the global accessory designer at adidas

Visit the headquarters and you’ll notice that the designers and marketers punch in on the same floor as those making the watches. All that separates the two groups is a glass wall, and creative director Mr Daniel Caudill sits as close to this transparent divide as anyone. The style-world veteran (who has occupied a top design position at adidas, as well as other creative posts) seems to like it that way.

“Design, interpretation and prototype are all done with people working right next to each other,” Mr Caudill explains, settling in at a walnut desk that wouldn’t look out of place at an honourable mid-century firm. After high-level assignments in Los Angeles and Dallas, he’s embraced the underappreciated energy of his new home city. “There is a lot happening here,” he points out, “art, culture, music, food.”

A watchstrap maker stitches the leather at her sewing machine

With the help of a Swiss watchmaker, Shinola has retrained local workers to assemble its watches

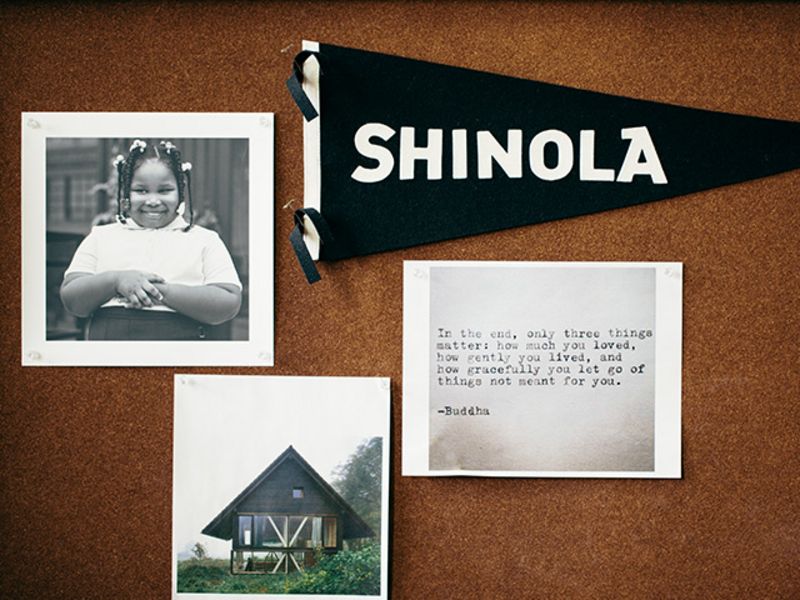

The cork moodboard that Mr Caudill keeps at his walnut desk

Being in Detroit, Mr Caudill admits, makes for good copy. But for a company aiming to be known worldwide for its American-made watches, it also makes sense. “Where do you go,” he asks, “to find people that are used to assembling product and small componentry, and who want to work?” Need, he might have added, citing the city’s unemployment rate for good measure.

“Where do you go to find people that are used to assembling product and small componentry, and who want to work?”

With help from a Swiss partner, Ronda, Shinola trained a battery of employees to assemble watch movements – no small feat, considering the chronographs contain no fewer than 124 components. It put a rigorous quality-check process in place. The style (classic, a little rugged) and price point (between £280 and £1,700, roughly) hit a sweet spot, and demand has soared to the point that Shinola is already increasing its annual watch production threefold – to 150,000 pieces – from last year. Not that capacity is being strained: the factory, when fully built out, can produce 500,000 watches a year.

Shinola’s classic style and affordable price point has seen production soar from 50,000 to 150,000 in the past year

New style brands launch all the time, but rarely in such bold fashion. Shinola came out of the vision (and considerable resources) of founder Mr Tom Kartsotis. His previous label, Fossil, scored big with mid-priced watches and leather goods. But especially in Detroit, and especially now, the momentum that Shinola is generating seems to be of a different order.

“The process for everyone involved is exciting, and it keeps building,” Mr Caudill says, gesturing toward the rows of concentrating watchmakers. “To build this factory in Detroit is a leap of faith. It’s by sheer will that this exists. There are many layers to this brand, but in a way it’s all based on that.”

“Leather is one of the things that ties all these categories together,” Mr Caudill says of Shinola's growing range

Shinola’s flagship Detroit store at 441 W Canfield Street

Shinola is the star child of a growing family: through his company, Bedrock, Mr Kartsotis has acquired a minority stake in the American label Steven Alan and, in 2012, bought the 117-year-old Seattle-based outerwear brand Filson.

On the creative side, Mr Caudill is overseeing brisk expansion of the current watch offerings. Dapper duffle bags and briefcases will soon be joining a portfolio of smaller leather goods that includes handmade wallets, journals and dog collars – the latter developed with input from noted photographer and canine lover Mr Bruce Weber, who shot them for the fall campaign.

Mr Larry Sanders, a 59-year-old former autoworker, embosses watch straps.“Crazy as it sounds, I like coming to work,” he says.

The factory, meanwhile, is busy pumping out watches and leather watchstraps. It is a process carried out by adaptive individuals. One worker, Mr Damond Love, 39, spent 15 years in the automotive industry and now prepares leather hides (sourced from Horween, a long-established tannery in Chicago) on machines called a clicker, a splitter and a long-strip cutter. “This job is quieter,” he notes, “and you don’t have people looking over your back all day.”

Nearby, a co-worker is using a hot plate to activate adhesive. A man named Mr Larry Sanders, who spent 18 years in the auto industry, is embossing Shinola into the watchstraps. Others are stitching and filing rough edges, while a 35-year-old woman named Ms Wendy Blackwell (who, in a previous job, processed paperwork for aspiring US citizens) is delicately applying black paint to the straps before feeding them into a small dryer. To visit is to realise how many steady hands and discerning eyes go into making this single, functional strap of leather.

Assembling the watch movements requires extreme precision

Each of these chronographs has 124 components

Things appear more subdued on the watch side, where workers wear smocks and hairnets to keep stray matter out of the delicate movements. They pick at watch innards with stylus and tweezers; the room is silent, save for the squeak of ubiquitous white clogs and the pneumatic hiss of pen-sized air guns.

On both sections of the factory, you notice employees wearing pricy Shinola timepieces. A seasoned watch technician named Mr Jalil Keazy, whose job is performing quality checks on the movements, announces that he owns four Runwells. “I’ve bought some for relatives and friends,” he adds. “And I’ve got my eye on a few more.”

Shinola’s bike frames are made in Wisconsin at a company owned by a member of the fabled Schwinn family

Mr Caudill, stylish in a trim uniform of workman’s indigo, explains the intentional coherence of the current product range. There’s the array of components that goes into watches and bicycles alike; there’s the metal-and-leather combo, and the fact that America can still produce both materials at a competitive price point.

For a company whose ambitions go well beyond the usual soft goods, Mr Caudill explains, there’s another reason to lead with watches. “They’re a complex product, and a hard one to set up and manufacture. So the fact that we’re doing this successfully, and the right way, is really proving that anything is possible.” Having nailed watches, getting into audio equipment, or lighting – both of which are on the table for Shinola – doesn’t seem so far out.

The bikes are then assembled on-site at the Shinola store…

…which was originally a warehouse for Willys-Overland Motors

Years ago, Shinola was the name of a popular shoe polish – that was part of the American vernacular (“You don’t know s*** from Shinola”) – and while the name has been brought back, Mr Caudill cautions against thinking of the new Shinola as a revival.

“To me, this is a completely modern brand. It works with how people live today,” he says – which means designs that don’t go out of style. Otherwise, Mr Caudill adds, what’s the point of Shinola offering a lifetime guarantee? “We want you to wear that watch 10 or 20 years from now.” He takes a glance at his own watch as the interview winds up, and at the uneven, sun-kissed skyline outside his window.

Wright & Co.

Mr CAUDILL’S Motor City Breakdown

“Its craft cocktails are amazing. I like to order El Diablo, which is made with ginger and tequila.”

Bucharest Grill

“There’s a really large Middle Eastern community in and around Detroit. The food that comes with that is great, but at Bucharest it’s phenomenal. I get their stuffed grape leaves and hummus.”

Bigalora

“The waffles that they serve for brunch here are a sure thing. They make them using their all-organic dough, housemade nutella, whipped cream and bananas.”

The Old Miami

“It’s a little seedy, but it’s also a cool, simple, laid-back music venue. Every time I show up there’s someone good playing – and usually local.”

Detroit Institute of Arts

“I’m a big fan. Because of the manufacturing and all the large companies, there’s an incredible amount of artwork here – in Detroit in general, and especially in this museum.”